ECOPAK™ FAQs

-

ECOPAK™ is made from recycled plastic bottles. Recycled polyester, whether repurposed as a jacket or ECOPAK™ fabric, can be recycled again.

There are two methods of recycling polyester:1) Mechanical: fabric is chopped up and re-used as filler for things like dog beds.

2) Chemical: Fabric is chopped up, melted down, and re-extruded as polyester fiber.

Currently, neither of these processes are readily available in the USA. The infrastructure for collection and recycling is still in its infancy. Hopefully in about 20 years, when bags made with ECOPAK™ have fulfilled their useful life, there will be readily accessible recycling stations.

-

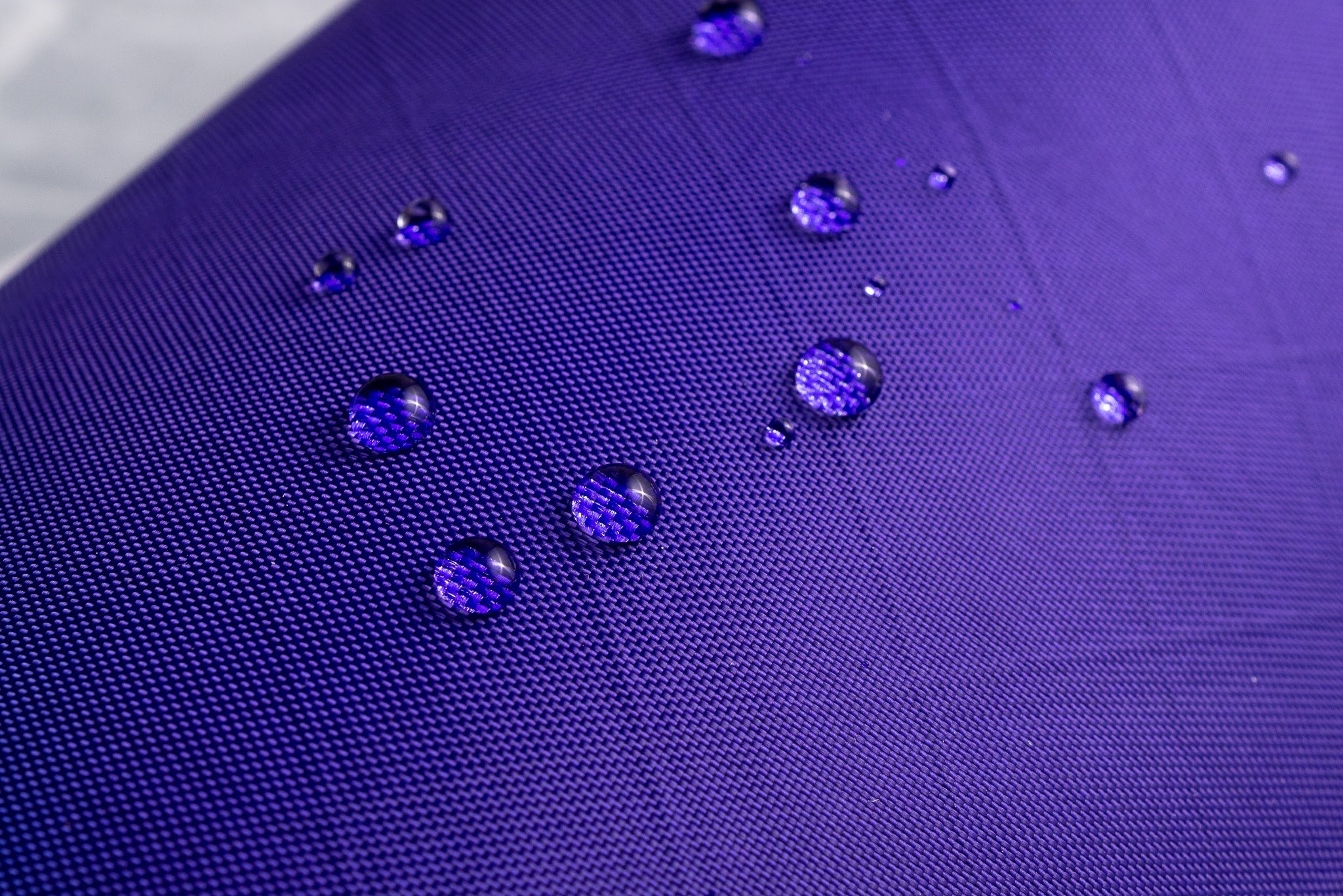

ECOPAK™ fabrics with our RUV™ film are 100% waterproof to 200 psi.

Our EPLX and ULTRA™ lines both use our RUV™ liner and are waterproof.Our EPX™ line of ECOPAK™ has a C0 DWR coating on the face and multiple thin waterproof coatings within the lamination. EPX is waterproof to 200+ psi.

Our RBC™ line is composed of woven fabrics coated with C0 DWR on the face and polyurethane coating on the back. They are highly water-resistant but not waterproof.

-

ECOPAK™ fabrics are made with components primarily sourced in Asia. Our fabrics are mostly woven at our facility in Thailand and laminated at our facility in China. This region of the world has the best infrastructure for recycling and manufacturing. Manufacturing in this region creates the biggest impact in reducing real-world carbon emissions. We take great care to ensure that our supply-chain is serviced with ethically sourced materials and labor. We maintain stock in the US and Asia to keep transportation emissions to a minimum.

-

The EPLX and ULTRA™ lines of ECOPAK both have our RUV™ film backing which is ideal for PSA tape. We sell two styles of PSA tape:

Ultra TNT PSA Tape:

This is two layers of .25mil polyester film with Ultra yarn reinforcement inside, and PSA backing.

It is waterproof and very stretch resistant, especially along the length of the roll, where there are straight, parallel Ultra yarns inserted to control stretch.

The Ultra CrossPly yarn helps control bias stretch, and adds to the tear-resistance of the tape.

It is designed to be applied to the film side of Ultra pack fabric to reinforce/waterproof seams; the Ultra yarns will not tear, and cannot be broken except under extremely high load.

Insignia tape:

This is 70d x 100d woven polyester with PSA backing.

It is designed for seam reinforcement for lightweight laminated sails, and is relatively stretchy.

It is applied to the film before stitching, to keep the thread from combing through the film.

It is also applied to the film on laminated sails, in large patches, to improve abrasion resistance where the sails rub against metal on the boat.

It is water-resistant, but not intended to be waterproof.

-

None of our ECOPAK™ fabrics are weldable as there is no TPU film to bond to.

-

EPX styles have a recycled 70d woven ripstop backing, so are heavier, but hold stitching better than the EPLX styles with film backing. The weight difference is about 1.5oz (51grams) per yard for EPLX200 compared to EPX200.

The EPLX has the advantage of being slightly lighter and works with PSA tapes for waterproofing seams. Note: if you are doing bar-tacks or daisy-chain webbing, the EPLX styles will need an extra fabric layer for reinforcement on the film backing to hold the stitching.

ULTRA™ FAQs

-

ULTRA™ fabrics use our RUV™ film backing and are waterproof to 200psi. U-PE fiber is naturally hydrophobic.

-

The ULTRA™ line is constructed with our RUV™ film backing which is ideal for PSA tape. We sell two styles of PSA tape:

Ultra TNT PSA Tape:

This is two layers of .25mil polyester film with Ultra yarn reinforcement inside, and PSA backing.

It is waterproof and very stretch resistant, especially along the length of the roll, where there are straight, parallel Ultra yarns inserted to control stretch.

The Ultra CrossPly yarn helps control bias stretch and adds to the tear-resistance of the tape.

It is designed to be applied to the film side of Ultra pack fabric to reinforce/waterproof seams; the Ultra yarns will not tear, and cannot be broken except under extremely high load.

Insignia tape:

This is 70d x 100d woven polyester with PSA backing.

It is designed for seam reinforcement for lightweight laminated sails, and is relatively stretchy.

It is applied to the film before stitching, to keep the thread from combing through the film.

It is also applied to the film on laminated sails, in large patches, to improve abrasion resistance where the sails rub against metal on the boat.

It is water-resistant, but not intended to be waterproof.

-

ULTRA™ fabric is constructed with a woven Ultra-PE / Polyester blend and laminated to our recycled Challenge RUV™ film. The blue polyester yarn in ULTRA™ 400 Midnight Blue is recycled.

-

ULTRA™ fabric is manufactured at our facility in China.